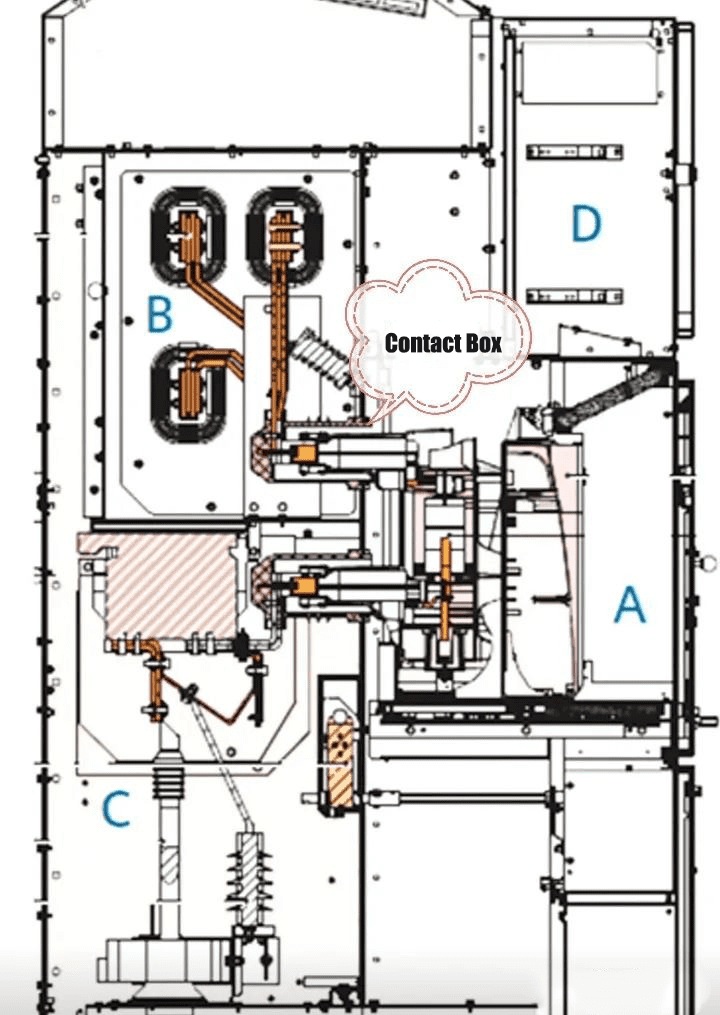

Medium-voltage metal-clad withdrawable switchgear cabinets require a contact box. The so-called contact box is actually a common name in the industry for an insulating sleeve used to install static contacts and to provide electrical isolation from grounded parts such as the mounting plate and the busbar phase.

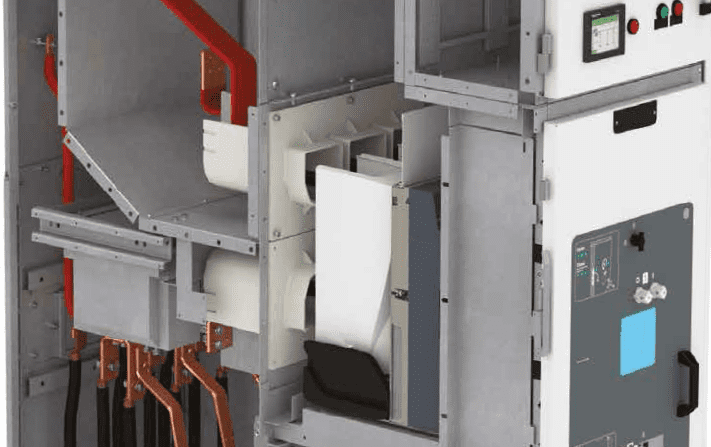

Why need contact box? Withdrawal type i.e. circuit breakers and other functional hand trucks need to be connected to the main circuit, hence the need for primary contacts. Why metal armoured? The definition of metal armoured switchgear cabinet, each functional compartment is completely separated by grounded metal plates, and the electrical connection between functional units is made by insulated parts, therefore metal armoured withdrawable switchgear cabinet, contact box and live door plate are needed to separate the busbar room and trolley room, the trolley room and the cable room, and static contacts connected to the branch busbar are fixed inside the contact box.

From the above description, it can be seen that the function of the contact box is phase-to-phase or ground insulation and isolation break insulation, static contact support, withstand the dynamic stability, protection and isolation function, of course, the insulation function is necessary, other static contact fixing as well as busbar support can be detached from the function of the contact box, such as through the insulator fixing, the contact box only to play the role of insulation.

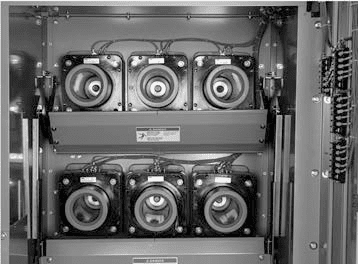

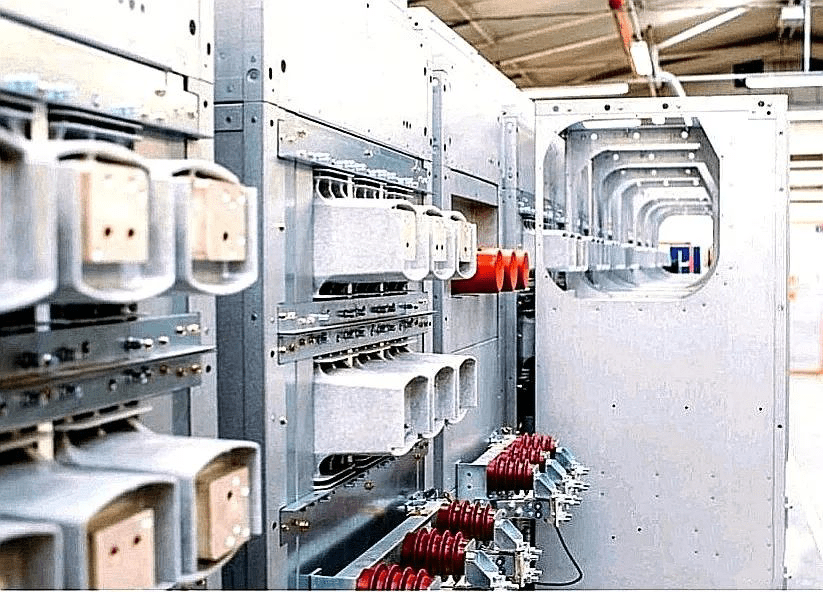

Typical contact box is the contact box for ZS1 and 28 cabinets, the branch busbar and static contacts are fixed on the metal inserts inside the contact box, the branch busbar extends to the main busbar or current transformer through the outlet of the upper part of the contact box, the size of the outlet is determined according to the current, i.e., the number of copper specifications, the typical type of the contact box is defined in terms of the width of the flange, e.g., 150/176/208/256 etc., for different currents, 150 for 650 mm. Typical contact box sizes are defined by the width of the flange, such as 150/176/208/256 for different currents, 150 for 650mm wide switchgear with 150mm phase spacing, and 208 for 210mm phase spacing with 800mm wide switchgear.

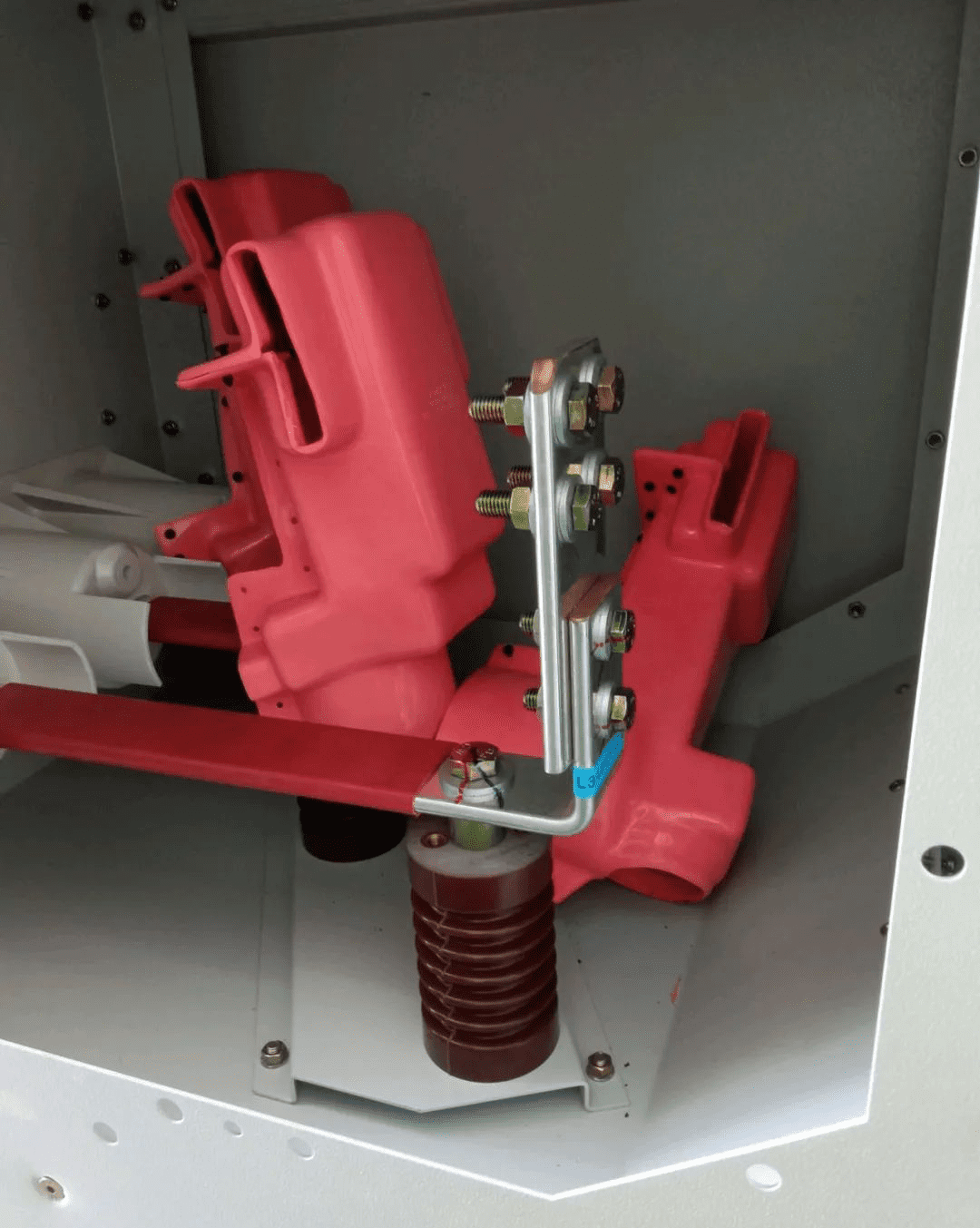

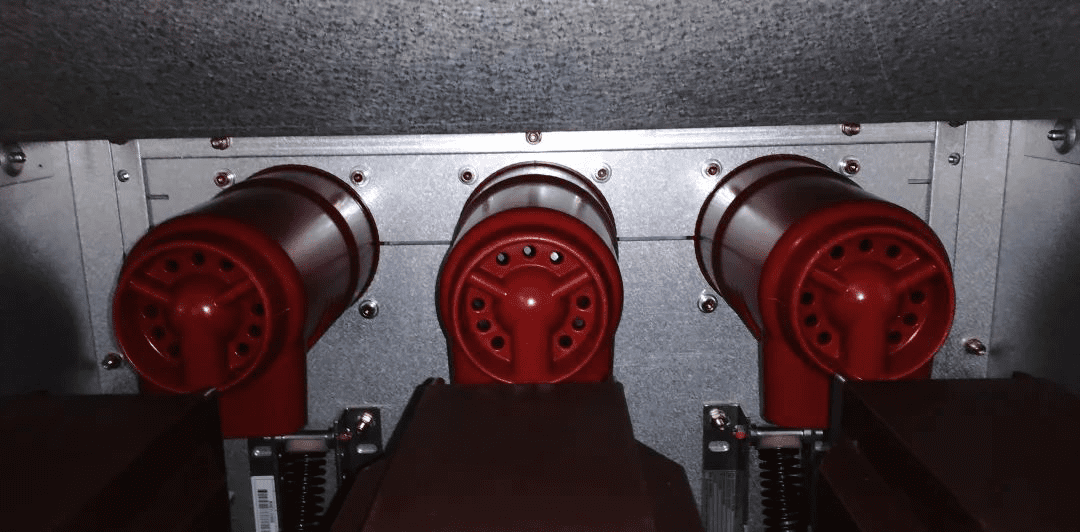

For 10kV contact box, generally do not need equalisation shielding, while 24kV and 40.5kV need to use contact box with equalisation shielding, high-voltage side and static contact contact equipotential, the external mounting inserts are connected to the metal mounting plate to form a ground, inside and outside the equalisation ring through the epoxy resin constitutes a capacitor, to withstand the high voltage.

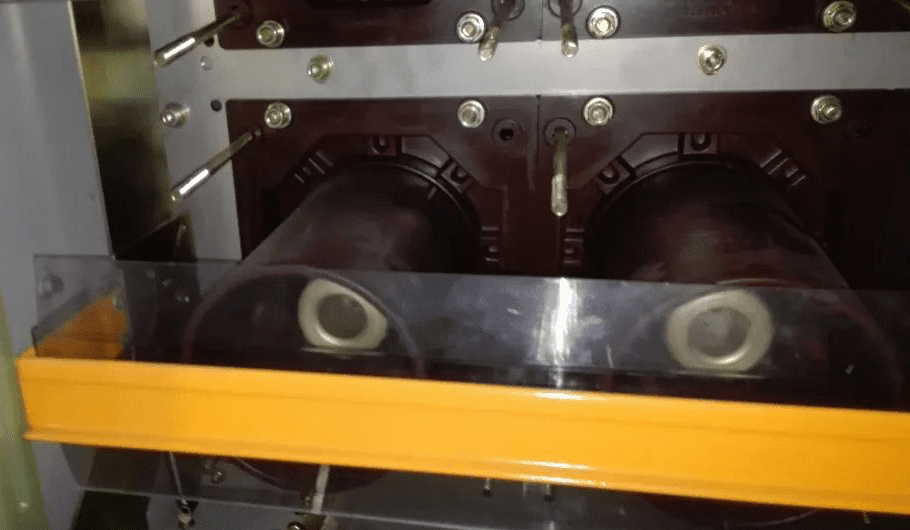

As the static contacts are sealed inside the contact box, the dynamic and static contacts are connected as well as the static contacts and branch busbar connections.

The front of the contact box is used to install the current transformer, or the rear is extended to install the current transformer.

The contact box is generally cast in epoxy resin, or DMC die-cast.

Due to the discharge between the mounting bolts of the contact box and the root of the contact arm of the circuit breaker, the rear mounting of the plate can ensure that there is no discharge between the front part of the contact box and the contact arm. The contact box has ventilation holes for heat dissipation.

The contact box fixes the busbar, the busbar and the static contact are directly connected, and the branch busbar can be installed with heat sink. The gap between the static contact and the contact box is used for ventilation.

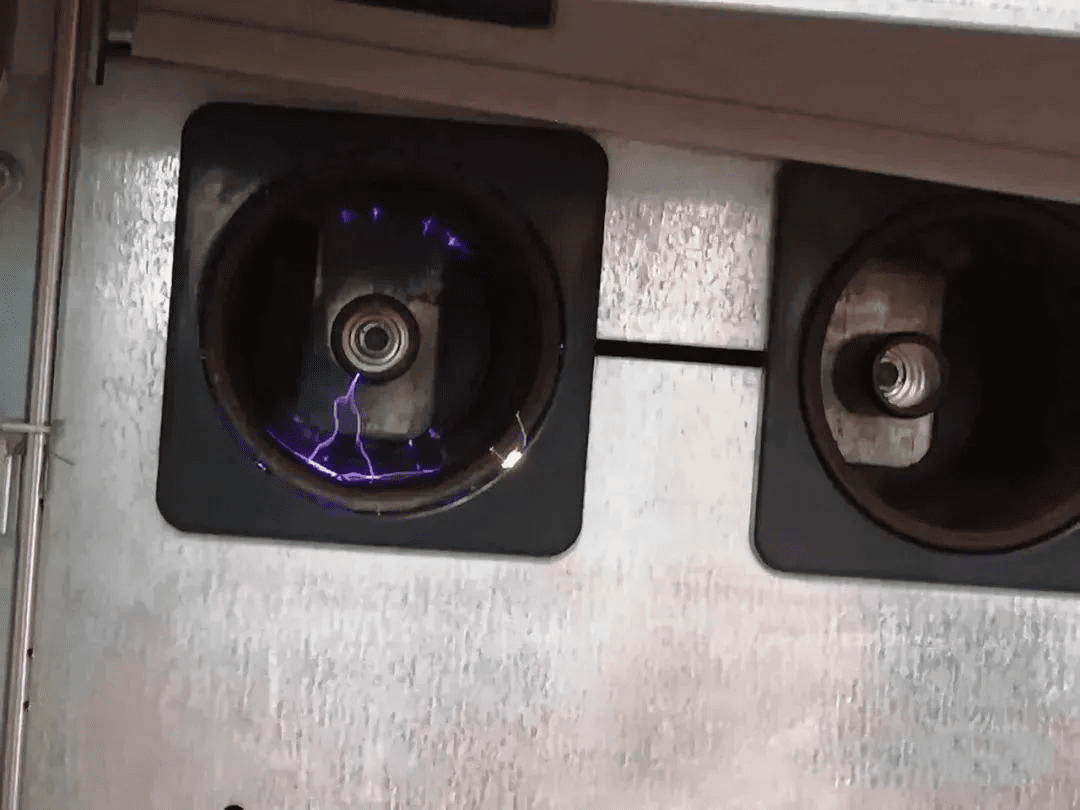

Contact box insulation has along the surface of the discharge, there are contact arms and contact box mounting plate between the direct breakdown discharge, the contact box along the inner umbrella skirt directly to the mounting plate discharge, first of all, some of the design of the inner umbrella skirt is virtually non-existent, there is no height difference between the umbrella skirt, there is not enough distance, so in the case of wet, or umbrella skirt some internal dirt, it will result in the ineffectiveness of the umbrella skirt, the electricity crosses the umbrella skirt direct discharge. Secondly, the contact box material is crucial, for the trace resistance of poor material, the arc is easy to crawl, the same voltage, in the insulating parts of the surface of the liquid medium, the arc crawls to the specified distance of the time spent determining the strength of the material trace resistance, according to the ANSI standard, this time is 300 minutes, and some materials are only ten minutes to the specified distance of the combustion. Therefore, materials with high resistance to electric traces can effectively avoid discharge along the surface.