Embedded Pole

Introduction:

Embedded pole refers to the integration of conductive components related to Vacuum interrupter and Circuit-breaker into solid insulating materials like epoxy resin or thermoplastic materials that can be easily cured. This integration forms a pole, making the entire circuit breaker pole a unified component.

Advantages:

Embedded pole offer the following two advantages:

Modular Design: They feature a simplified structure with fewer detachable components, leading to higher reliability.

High Insulation Capability: It transforms surface insulation into volume insulation, reducing the environmental impact significantly compared to air insulation and greatly enhancing insulation strength.

Embedded poles enable the reduction of the circuit breaker’s size, which is beneficial for compact switchgear.

In the past, the insulation housing of conventional vacuum interrupters was exposed to the atmosphere, leading to issues such as dust and humidity contamination. To mitigate these problems, longer insulation housings were required, which not only hindered miniaturization but also affected the performance and reliability of vacuum interrupters. Embedded poles offer several advantages:

Compared to traditional assembled poles, embedded poles significantly reduce the number of components. The number of conductor interfaces is reduced from 6 groups to 3 groups, and the number of connecting bolts is reduced from 8 to 1-3, simplifying the structure and greatly improving the reliability of circuit breakers.

Since the vacuum interrupter is embedded in solid material, no further treatment is needed to achieve high insulation strength.

With the vacuum interrupter embedded in solid material, the impact of the external environment on the pole’s insulation is minimized.

Manufacturing:

Embedded poles are created by curing vacuum interrupters and conductive terminals, among other components, using epoxy resin to form an integrated pole. Since the vacuum interrupter is sealed within the epoxy resin, it is almost unaffected by external contaminants and humidity. Epoxy resin serves not only as the primary insulation but also as the mechanical support for the interrupter. This results in a better electric field distribution compared to traditional assembled poles. Additionally, the reduced number of structural components enhances the reliability of the conductive circuit. The use of embedded poles is becoming increasingly widespread.

Currently, embedded poles can be further categorized into two main production processes.

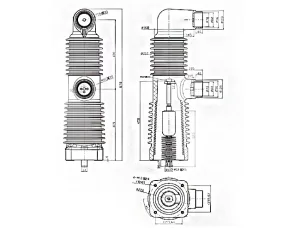

Embedded Pole:

The surface of the vacuum interrupter is sulfurized, and then the interrupter, along with conductive components, is assembled and placed in a mold. Epoxy resin is poured into the mold and cured to create the integrated pole.

Resin-Encapsulated Pole:

The vacuum interrupter and conductive components are assembled and secured within a prefabricated epoxy resin insulating tube. Silicone rubber is injected into the gap between the vacuum interrupter and the insulating tube, and it is cured to form the integrated pole.

These processes enhance the insulation and reliability of circuit breakers while simplifying their design.